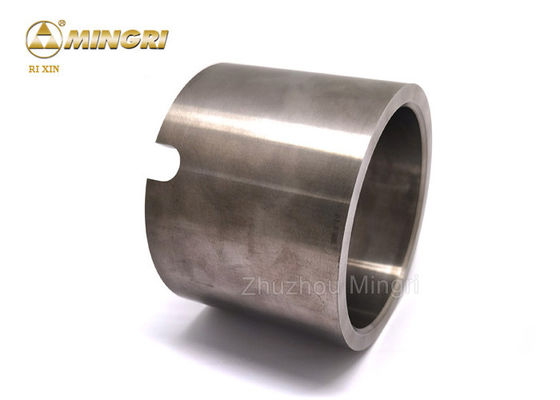

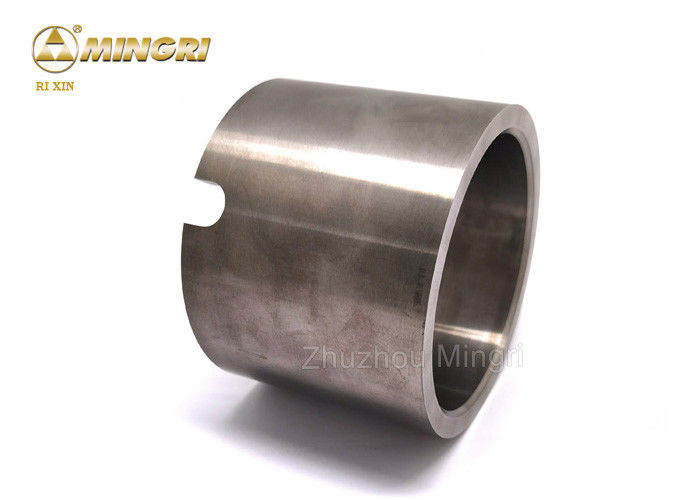

ML35 grade tungsten Cemented Carbide Grinding Roller Ring

Product Details:

| Place of Origin: | China |

| Brand Name: | Rixin |

| Certification: | ISO 9001:2008 |

| Model Number: | ML35 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1KG |

|---|---|

| Packaging Details: | Cartons |

| Delivery Time: | 7-15 days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50+tons+per month |

|

Detail Information |

|||

| Product Name: | Carbide Roller Ring | Material: | Tungsten Carbide |

|---|---|---|---|

| Application: | Finishing Rollers | Grade: | ML35 |

| Surface Finish: | Rough/fine Machining | Pacakge: | Standard Cartons |

| Usage: | Steel Industries | Key Words: | Carbide Roller Ring |

| Surface: | Grinding | ||

| High Light: | Carbide Grinding Roller Ring,ML35 Cemented Roller Ring,Tungsten Grinding Roller Ring |

||

Product Description

RIXIN brand ultra thin design tungsten cemented carbide grinding roller ring

Production Description of carbide roller ring

Carbide roller ring also called tungsten carbide roll collar, it refers to the roll made from tugnsten carbide and cobalt by powder metallurgy. Tungsten carbide roller rings are available in both integral and combined versions. They have excellent performance, stable quality ,high processing precision, good wear resistance, and high impact resistance.

With the increasingly fierce competition in the quality and price of steel products, steel companies are costantly updating their equipment technology to continously increase the rolling speed of rolling mills. At the same time, how to reduce the rolling mill downtime and further improve the effective operation rate of rolling mills ? It has become an important topic for rolling steel engineers. The use of roll materials with higher rolling life if one of the important means to achieve this goal.

|

Material

|

Tungsten Carbide |

|

Hardness

|

HRA 84.0 |

|

Supply Capability

|

5000 Pieces/Month |

Production Advantage of tungaten carbide roller ring

The tungsten carbide rollers have high hardness, and its hardness changes very little with temperature changes. The hardness at 700 °C is 4 times that of high-speed steel; and the elastic modulus, compressive strength, flexural strength, and thermal conductivity are also over 1 times higher than tool steel.

Since the thermal conductivity of the cemented carbide roll is high, the heat dissipation effect is good, and the time at which the surface of the roll is at a high temperature is short so that the high-temperature reaction time between the roll and the harmful impurities in the cooling water is short. Therefore, the cemented carbide roll is more resistant to corrosion and cold and hot fatigue than the tool steel roll.

![]()